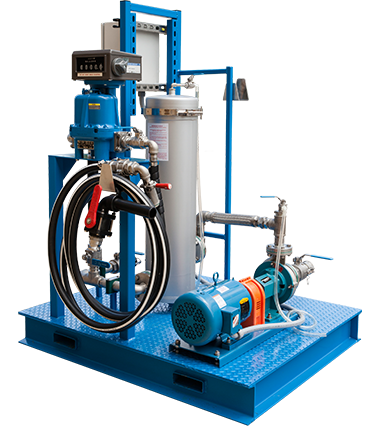

Transport/Drum & Tote(IBC) Filling:

Dual Purpose Stationary Filling System

This filling system is equipped with Weights and Measures approved meter for filling Drums & Totes at 2-50 GPM with precision and accuracy.

It also allows for bypassing the meter to fill transports at rates of up to 150 GPM! This dual-purpose system comes fully assembled on a forklift compatible skid and can be easily installed.

Dimensions/Specifications

- Weights & measures approved meter

- System flow rates of 2 to 50 GPM

- TCS 682 stainless steel piston meter

- Resettable register

- Stainless steel straight centrifugal pump

- Capable of 150 GPM at 75 feet of head

- DEF compatible seal

- 5 HP 220v 1 or 3 phase TEFC motor

- Pre-assembled and pre-wired

- 4'x4' Powder-coated frame (6ft high system)

- Forklift compatible

- 20' of 1 1/2" Suction hose

- 1 1/2" Transport fill line bypassing the meter

- Manual valve to control discharge flow rate to drum & tote

- 2" Flanged stainless steel filter with seven 1-micron absolute filter cartridges

- DEF-compatible stainless steel valves, camlocks, & plumbing

- 25' of 1 1/2" Discharge hose for transport fill with stainless steel NPT ends

- 25' of 1" Discharge hose for drum & tote fill

- 1 1/2" Poly fill nozzle & Micro Matic RSV fill valve

- Hose hangers

Drum & Tote(IBC)

Stationary Filling System

This filling system is equipped with Weights and Measures approved meter for filling Drums & Totes at 2-28 GPM with precision and accuracy.

This system comes fully assembled on a forklift compatible skid for easy installation. All wetted parts are DEF compatible and sealed for a contaminant-free environment.

Dimensions/Specifications

- Weights & measures approved meter

- System flow rates of 2 to 28 GPM

- TCS 682 stainless steel piston meter

- Resettable register

- 1 1/2" Stainless steel self-priming pump

- DEF compatible seal

- 1 HP 110v 1 phase TEFC motor

- Electrical power control panel switch (10 amp circuit required)

- Pre-assembled and pre-wired

- 4'x4' Powder-coated frame (6ft high system)

- Forklift compatible

- 20' of 1 1/2" Suction hose

- Manual valve to control discharge flow rate to drum & tote

- Stainless steeel filter with five 10-micron absolute filter cartridges

- DEF-compatible stainless steel vavles, camlocks, & plumbing

- 110v Electric-rewind hose reel

- 50' of 1 1/4" Discharge hose

- 1 1/2" Poly fill nozzle

- 1 1/2" Poly fill nozzle & Micro Matic RSV Fill Valve